除湿干燥机 |

|

|

|

除湿干燥机 |

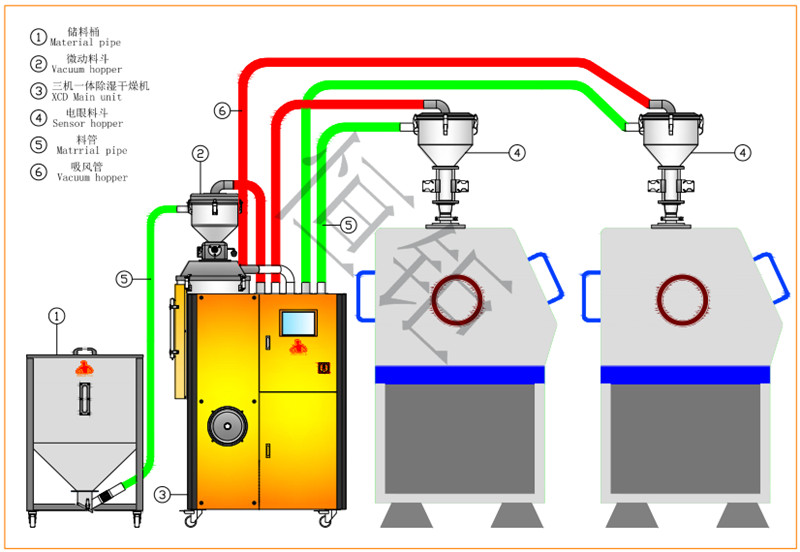

除湿干燥机主要是对塑料塑胶树脂原料进行除湿和干燥的自动化设备;在生产塑料塑胶或树脂产品时去除塑料或树脂原料中的水分(例如:工程塑料,PET,PE,PBT,PC等原料),并解决产品所产生的气泡,银纹,裂纹和产品稳定性差的问题,并提高产品质量; 除湿干燥机主要是对塑料塑胶树脂原料进行除湿和干燥的自动化设备;在生产塑料塑胶或树脂产品时去除塑料或树脂原料中的水分(例如:工程塑料,PET,PE,PBT,PC等原料),并解决产品所产生的气泡,银纹,裂纹和产品稳定性差的问题,并提高产品质量;除湿干燥机工作原理: 除湿干燥机的风道为封闭式循环系统,并同时进行过滤。从干燥料桶回来的湿热空气经冷却,吹入蜂巢转轮,空气中的水分被转轮吸附,然后又被再生加热空气所脱附。1.两股气流同时作用在转轮上,并随着转轮的转动,使得空气中的水分连续不断的被吸附又被再生空气所脱附而排出,就形成稳定的低露点空气,经加热到塑料的干燥温度,吹入干燥料桶内,形成密闭循环,干燥原料。 2.吸料部分,吸料是从储料桶或其它储料仓容器中吸入干燥料桶内,当真空料斗的磁簧开关侦测到无料时,吸料马达运转,使真空料斗内产生真空。 3.储料桶中的原料由于空气的压力差被吸入真空料斗内,当 吸料时间完成后,吸料马达停止运转,原料会因自重落入干燥料桶内,经干燥后的原料从干燥料桶抽到安装在塑料成型机的电眼料斗内。 4.除湿机的内循环:通过压缩机的运行→排气口排出高温高压的气体→进入冷凝器冷却→变成低温高压气体→通过毛细管截流→变成低温低压的液体→通过蒸发器蒸发吸热→回到压缩机变成低温低压的气体。如此循环往复。 5.除湿机的外循环:在正常开机的情况下→通过风机的运行→潮湿的空气从进风口吸入→经过蒸发器→蒸发器将空气中的水份吸附在铝片上→变成干燥的空气→经过冷凝器散热→从出风口吹出。 除湿干燥机特点: 除湿干燥机不受外来者的影响,物料可在干燥或潮湿的天气下干燥,而不会逆转水分,节能环保,防止粉尘污染工厂,改善工作环境,缩短干燥时间,节省工作时间,改善了传统热风机的缺点。除湿干燥机特点:  除湿干燥机主要是对塑料塑胶树脂原料进行除湿和干燥的自动化设备;在生产塑料塑胶或树脂产品时去除塑料或树脂原料中的水分(例如:工程塑料,PET,PE,PBT,PC等原料),并解决产品所产生的气泡,银纹,裂纹和产品稳定性差的问题,并提高产品质量; 除湿干燥机主要是对塑料塑胶树脂原料进行除湿和干燥的自动化设备;在生产塑料塑胶或树脂产品时去除塑料或树脂原料中的水分(例如:工程塑料,PET,PE,PBT,PC等原料),并解决产品所产生的气泡,银纹,裂纹和产品稳定性差的问题,并提高产品质量; |

除湿干燥机设备 |

| 节能除湿干燥机 | 塑料结晶除湿干燥机 | 塑料除湿机 |

|

|

|

| 塑料除湿干燥机 | 蜂巢除湿干燥机 | 料斗除湿干燥机 |

|

|

|

| 标准除湿干燥机 | 二机一体除湿干燥机 | 三机一体除湿干燥机 |

|

|

|

除湿干燥机应用 |

| 除湿干燥机在PET材料上应用 | 除湿干燥机在吹瓶中应用 | 除湿干燥机在树脂工业中应用 |

|

|

|

| 除湿干燥机在PE行业的应用 | 除湿干燥机在TPU行业的应用 | 除湿干燥机在PPO行业的应用 |

|

|

|

| 除湿干燥机应用中央供料系统 | 注塑行业除湿干燥机 | 吹塑工业用除湿干燥机 |

|

|

|

除湿干燥机的所有信息,PDF文件下载 |

除湿干燥机对应的原材料参数 |

|

Plastic |

干燥 |

密度 |

干燥时间(h) |

干燥温度 |

大气流量(m3/kg) |

成型含水量(%) |

初始水分(%) |

| ABS | √ | 0.55 | 2-3 | 85 | 2 | <0.020 | <0.2 |

| CAB | √ | 0.60 | 2-3 | 70 | 2 | 0.020 | 0.6 |

| EVA(2) | √ | 0.60 | 2-3 | 90-105 | 1.8 | - | - |

| EVOH | √ | 0.60 | 2-3 | 90-105 | 2 | - | - |

| LM(4) | √ | 0.50 | 3 | 600 | 2 | 0.080 | <0.2 |

| LCP | √ | 0.80 | 3-4 | 150 | 2.2 | <0.01 | <0.05 |

| PA11 | √ | 0.60 | 3-5 | 70-80 | 2 | - | <0.6-1.2* |

| PA | √ | 0.83 | 6-8 | 180 | 1.23 | <0.03 | - |

| PA66 | 0.60 | 4-6 | 70-80 | 2 | <0.15-0.02* | <0.6-1.2* | |

| PAI | √ | 0.85 | 6-8 | 180 | 2 | <0.02 | - |

| PAR | √ | 0.70 | 5-6 | 120 | 2 | <0.02 | - |

| PBT | √ | 0.80 | 3-4 | 130-140 | 2.2 | <0.02 | <0.15 |

| PC | √ | 0.65 | 2-3 | 120 | 2 | <0.02 | <0.3 |

| PC/ABS | √ | 0.65 | 42798 | 100 | 2 | <0.020 | <0.1 |

| PC/PBT | √ | 0.75 | 3-4 | 110 | 2.2 | - | - |

| PE.HDEPE. LDPE black3% |

√ | 0.50 | 1 | 85 | 1.6 | <0.01 | <0.02 |

| PE.HDEPE. LDPE black40% |

√ | 0.70 | 2-3 | 80-90 | 2 | <0.02 | <0.2 |

| PEEK | √ | 0.80 | 3-4 | 150-160 | 2.2 | <0.05 | <00.1 |

| PE(1)(3) | √ | 0.75 | 4-5 | 140-160 | 2.5 | <0.01 | <0.2 |

| PEN(1)(3) | √ | 0.86 | 5-6 | 150-170 | 3 | <0.005 | - |

| PES | √ | 0.80 | 3-4 | 150-180 | 2 | <0.05 | <0.35 |

| PET | √ | 0.84 | 5-6 | 160-180 | 3 | <0.003 | <0.2 |

| PETG | √ | 0.74 | 4-5 | 65 | 3.5 | <0.01 | <0.1 |

| PI | √ | 0.70 | 2-3 | 120 | 2.2 | <0.02 | - |

| PMMA | √ | 0.65 | 3-4 | 80 | 3 | <0.02 | <0.3 |

| POM | √ | 0.85 | 2-3 | 90-100 | 2 | - | <0.15 |

| PP | √ | 0.50 | 1 | 80-90 | 2 | - | - |

| PPO | √ | 0.55 | 2 | 100-110 | 2 | <0.01 | - |

| PPS | √ | 0.80 | 2-3 | 130-140 | 2 | <0.01 | <0.03 |

| PS [GPPS.EPS.HIPS] |

√ | 0.55 | 1 | 80 | 1.7 | <0.02 | <0.05 |

| PSU | √ | 0.80 | 3-4 | 120-130 | 2 | <0.05 | <0.1 |

| PIT | √ | 0.80 | 5-6 | 130-150 | 3 | <0.05 | <0.2 |

| PUR | √ | 0.75 | 2-3 | 70-90 | 2 | 0.02 | - |

| PVC | √ | 0.85 | 1 | 70-80 | 1.4 | <0.02 | - |

| SAN | √ | 0.55 | 2-3 | 80 | 2 | <0.02 | <0.1 |

| SB | √ | 0.60 | 1-2 | 80 | 2 | <0.02 | - |

| TPE | √ | 0.65 | 2-3 | 110 | 2.2 | 0.05 | <0.3 |

| TPE | √ | 0.65 | 2-3 | 80 | 2.2 | <0.1 | - |

| TPO | √ | 0.55 | 3 | 70-90 | 2 | - | - |

| TPU | √ | 0.75 | 2-3 | 70-100 | 2 | <0.02 | - |

塑料除湿干燥机的工作原理图 |

除湿干燥机组件 |

|

除湿干燥机控制器: |

|

除湿干燥机(塑料干燥机)吸料系统: 吸力从存储桶或其他存储容器中被吸入干燥桶中。 当真空储料器的磁簧开关检测到没有材料时,吸气马达运行以在真空储料器中产生真空,而储料桶中的原料由于气压差而被吸到真空中 料斗,但在完成抽吸时间后,抽吸电机停止运行,原料将自动掉入干燥的料斗中。 干燥后的原料从干燥桶中泵送到安装在塑料成型机中的电眼料斗或其他料斗中。 要查看更多产品信息,请单击此处--- (除湿干燥机(塑料干燥机)吸料系统) |

|

除湿干燥机干燥系统: 从干燥桶返回的湿热空气被冷却并吹入蜂窝状流道。 空气中的水分被流道吸收,然后被再生加热空气解吸。 两种气流同时作用在流道上,并且随着流道的旋转,空气中的水分被不断吸收,然后被再生空气解吸,从而排出,形成稳定的低露点空气,将其加热 到塑料将干燥温度吹入干燥桶以形成一个封闭的循环来干燥原料。 要查看更多产品信息,请单击此处- (除湿干燥机干燥系统) |

|

除湿干燥机料斗: 环保的滤芯可有效去除干燥机中的杂质; 它可以防止粉尘泄漏在工厂造成污染,并保持空气环境清洁。 要查看更多产品信息,请单击此处- (除湿干燥机料斗) |

|

除湿干燥机(塑料干燥机)电控箱: 自动控制整个除湿干燥机的运行,使工作人员可以随时掌握机器的变化;(比如(PC、PE、PET、PLA、PP、尼龙等)在生产过程中有多种样式机型,例如三合一,专用,蜂窝,标准和常见类型! 要查看更多产品信息,请单击此处- (除湿干燥机电控箱) |

|

除湿干燥机过滤器: 环保的滤芯可有效去除干燥机中的杂质; 它可以防止粉尘泄漏在工厂造成污染,并保持空气环境清洁。 要查看更多产品信息,请单击此处 --(除湿干燥机过滤器) |

|

除湿干燥机(塑料干燥机)热风道: 凭借自身的优势可以稳定整个身体,并有效地阻止多余的水分通过热风道! 要查看更多产品信息,请单击此处-(除湿干燥机热风管) |

|

除湿干燥机(塑料干燥机)风机: 是除湿干燥机的除湿和干燥的重要部分,热风机是把热量传送给主机的组成部分 要查看更多产品信息,请单击此处-(除湿干燥机风机) |

除湿干燥机技术与设备 |